GYPSUM BONDED INVESTMENTS

Thermal behaviour of gypsum

When gypsum is heated to a high temperature, it shrinks and fractures. At 700 °C, it shows slight expansion and then great amount of contraction. The shrinkage is due to decomposition and release of sulphur dioxide .

It contaminates the casting with sulphides of silver and copper .

Hence gypsum bonded investments are not heated above 700°C.

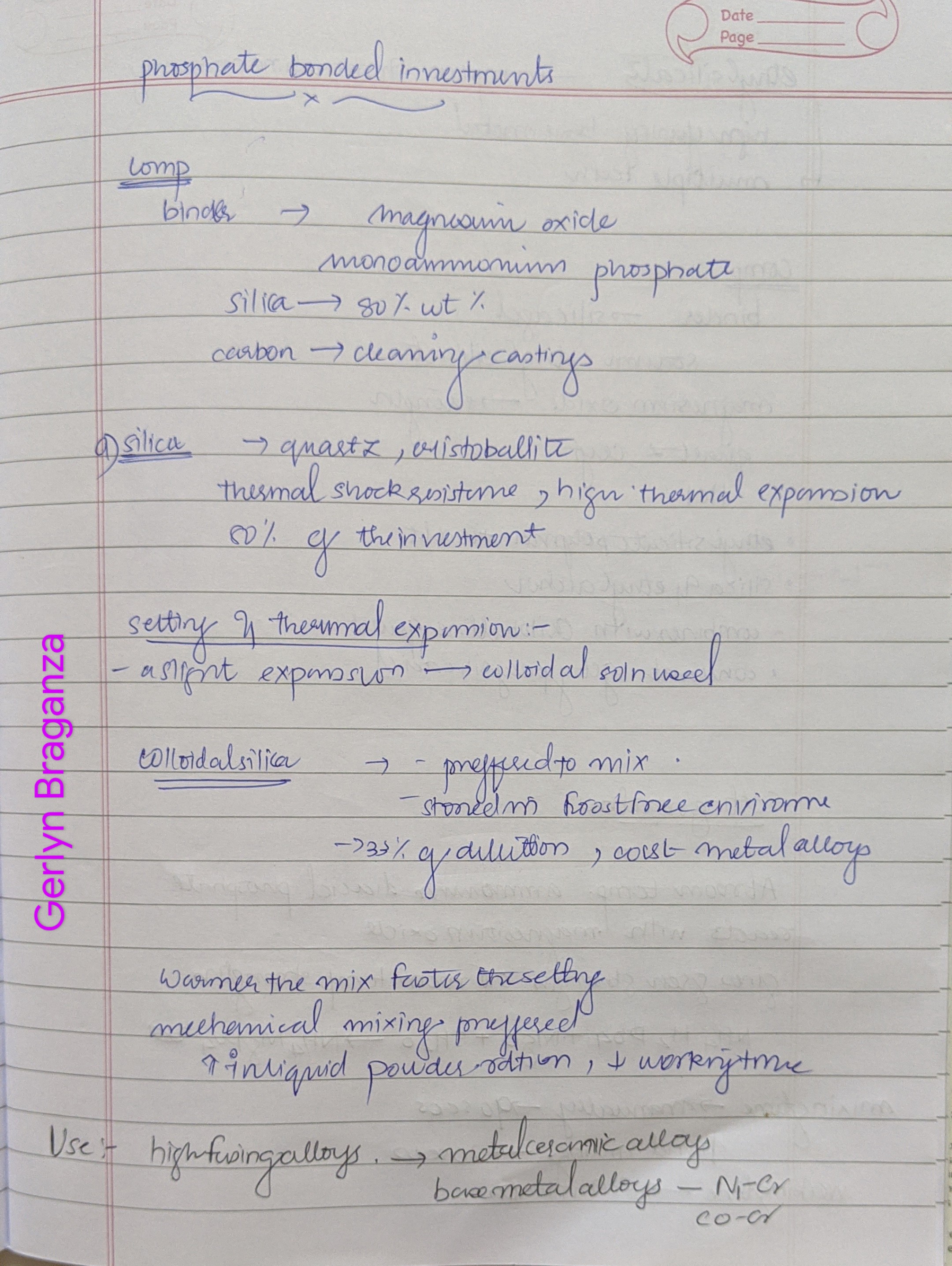

PHOSPHATE BONDED INVESTMENTS

EXPANSION

- Wax pattern expansion The heat during setting allows a significant expansion of the wax pattern

- Setting expansion This is around 0.7 to 1%.

- Thermal expansion Ranges from around 1 to 1.5%.

The amount of expansion is adjusted by the manufacturer for each product depending on the alloy it is intended for.

STRENGTH –

Wet strength ranges from 4-10Mpa

And dry strength is the strength under high temperatures.

SILICA BONDED INVESTMENTS

The silica is the binder. It is derived from ethyl silicate or aqueous dispersion of colloidal silica or sodium silicate.

TYPES

Based on the binder used two types may be seen. One such investment consists of silica refractory, which is bonded by the hydrolysis of ethyl silicate in the presence of hydrochloric acid.

The product of the hydrolysis is the formation of a colloidal solution of silicic acid ethyl alcohol.

Ethyl silicate has the disadvantage of containing inflammable components which are required for manufacture

Sodium silicate and colloidal silica are more commonly used as binders because of the above disadvantage.

These investments are supplied along with two bottles of special liquid. One bottle contains dilute water soluble silicate solution such as sodium silicate.

Source – basic science of dental materials manappallil