Synonyms: Crown and bridge cement, Zinc oxyphosphate

APPLICATIONS:

Luting of restoration and orthodontic bands & brackets

Thermal insulation

Root canal restoration

High strength bases

Temporary restoration

CLASSIFICATION:

| PARTICLE SIZE | FILM THICKNESS | USE | |

| TYPE 1 | Fine | 25um | Luting |

| TYPE 2 | Medium | 40um | Luting, base |

SETTING OF THE CEMENT:

Phosphoric acid in the liquid dissolves zinc oxide and reacts with aluminium phosphate to form aluminium phosphate gel on the remaining undissolved zinc oxide particles.

SETTING TIME: 2.5 to 8 minutes

MANIPULATION:

It is an exothermic process.

Zinc oxide cement is dispensed on the glass slab and divided into 6 increments(1/16, 1/16, 1/8, 1/4, 1/4, 1/4). It is followed by dispensing of the liquid.

Mixing of the cement should be initiated by the smallest increment with a thin spatula. There should be brisk spatulation with large, wide circular motions to dissipate the heat.

When the spatula is drawn away from the mixture, a strand of 12-19 mm should be produced. Such cement is suitable for cementation.

MIXING TIME:

For each increment: 15-20 sec

Total mixing time: 1.5-2 min

PROPERTIES:

MECHANICAL PROPERTIES: Compressive strength = 104 MPa, Tensile strength = 5.5 MPa, Elastic modulus = 13 GPa

SOLUBILITY: Less soluble in water (0.06%). Soluble in lactic, acetic and citric acids (in-vivo)

ADHESION TO TOOTH: Mechanical bonding ( In case of application of a cavity liner before applying zinc phosphate, it does not bond well due to less retention as it will create smoother surface with less interlocking)

BIOLOGICAL PROPERTIES: Phosphoric acid is acidic and cytotoxic. Younger patients are more susceptible to it because of more open dentinal tubules. Older patients with sclerotic dentin have a tortuous path for the entry of acid.

The biological considerations of dental materials cannot be isolated from their physical properties.

Biological requirements of Dental Materials

A dental material should:

2. Be non-irritant to the oral or other tissues.

3. Not produce allergic reactions.

4. Not be mutagenic or carcinogenic.

Examples of hazards from chemicals in Dental Materials

✔Some dental cements are acidic and may cause pulp irritation.

✔Polymer based filling materials may contain irritating chemicals such as unreacted monomers, which can irritate the pulp.

✔Phosphoric acid is used as an etchant for enamel.

✔Mercury is used in dental amalgam, mercury vapor is toxic.

✔Dust from alginate impression materials may be inhaled, some products contain lead compounds.

✔Monomer in denture base materials is a potential irritant.

✔Some people are allergic to alloys containing nickel.

✔During grinding of beryllium containing casting alloys, inhalation of beryllium dust can cause berylliosis.

✔Some dental porcelain powders contain uranium.

✔Metallic compounds (e.g. of lead and tin) are used in elastomeric impression materials.

✔Eugenol in impression pastes can cause irritation and burning in some patients.

✔Laboratory materials have their hazards, such as: cyanide solution for electroplating, vapours from low fusing metal dies, siliceous particles in investment materials, fluxes containing fluorides, and asbestos.

✔Some periodontal dressing materials have contained asbestos fibres.

REFERENCES:

1.Textbook of Dental Materials – John J Manappallil

2.Images – Google

AMALGOMER Technology is the latest innovation in restorative dentistry. For the first time the strength of a classic amalgam restorative has been combined with the aesthetics and the many other advantages of Glass Ionomers.

In short AMALGOMER is the world’s first GIC to pass the ISO strength test requirements for amalgam (ISO1559:2001) as well as that of the GIC standard (ISO9917:1991).

Features:

Amalgomer CR High Strength Posterior GI

AMALGOMER CR High Strength Posterior GI Restorative offers a wide range of features:

1) Ceramic Reinforcement

2) Exceptionally low wear

3) High Radiopacity

4) Excellent for core build ups

5) High strength, exceeds 300MPa compressive strength

6) Universal tooth shade or white

7) Natural Adhesion to tooth structure

Amalgomer High Strength Anterior GI

AMALGOMER High Strength Anterior GI Restorative offers a wide range of features:

Amalgomer Light Cure Varnish

A light curable varnish for protection of AMALGOMER and AMALGOMER CR restorations. This protects the restoration against moisture. This can be used with any GI restorative.

Amalgomer Conditioner

Dentine conditioner for use prior to placing AMALGOMER and AMALGOMER CR restorations.

Amalgomer mixing spatulas

Flexible plastic glass ionomer mixing spatulas.

Dr Iswarya V

General Practitioner,

Trivandrum.

Reference : Amalgomer official product website

Tap to View in full size…⬇️

References: Phillips Science of Dental materials 12th Ed.

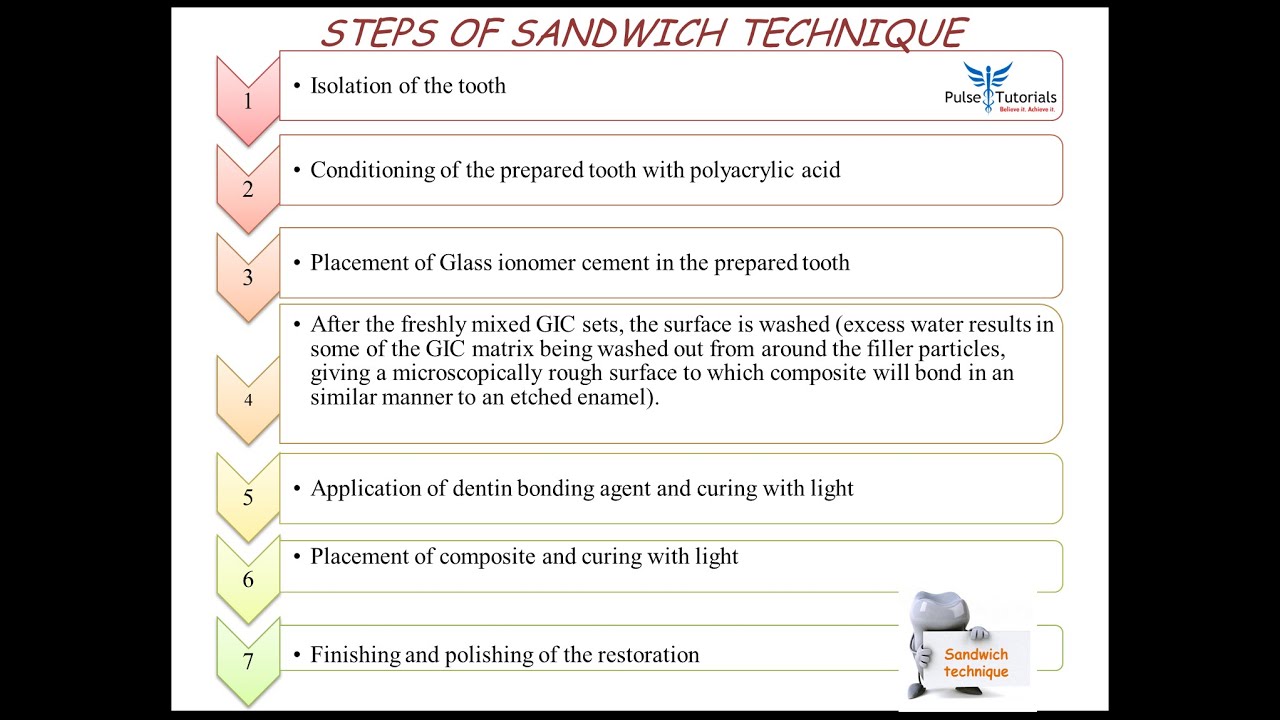

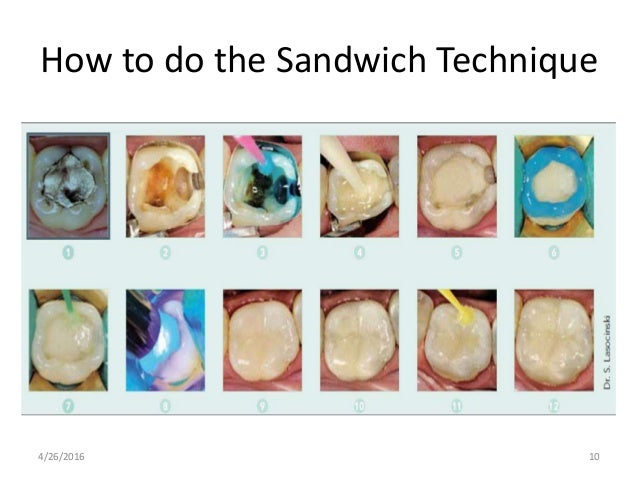

So what is this sandwich technique? Is it associated with the edible sandwiches ?

No!

In fact it is associated with a technique in dentistry. So it looks something like this . Lets see what,why, and how is it used !

GIC can be etched with phosphoric acid which helps in retention.

source – textbook of dental materials (manapallil), philips, slide share and google images

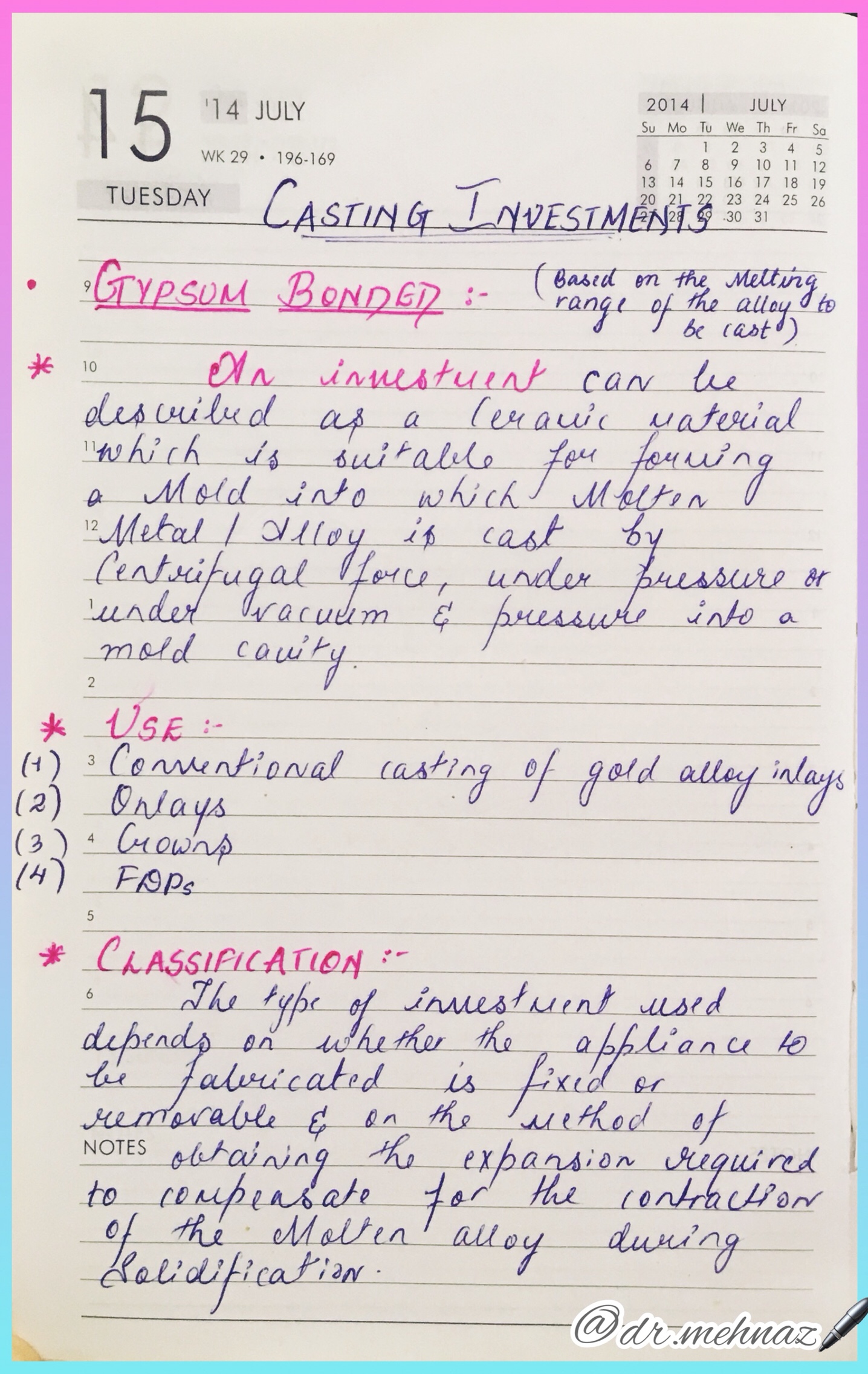

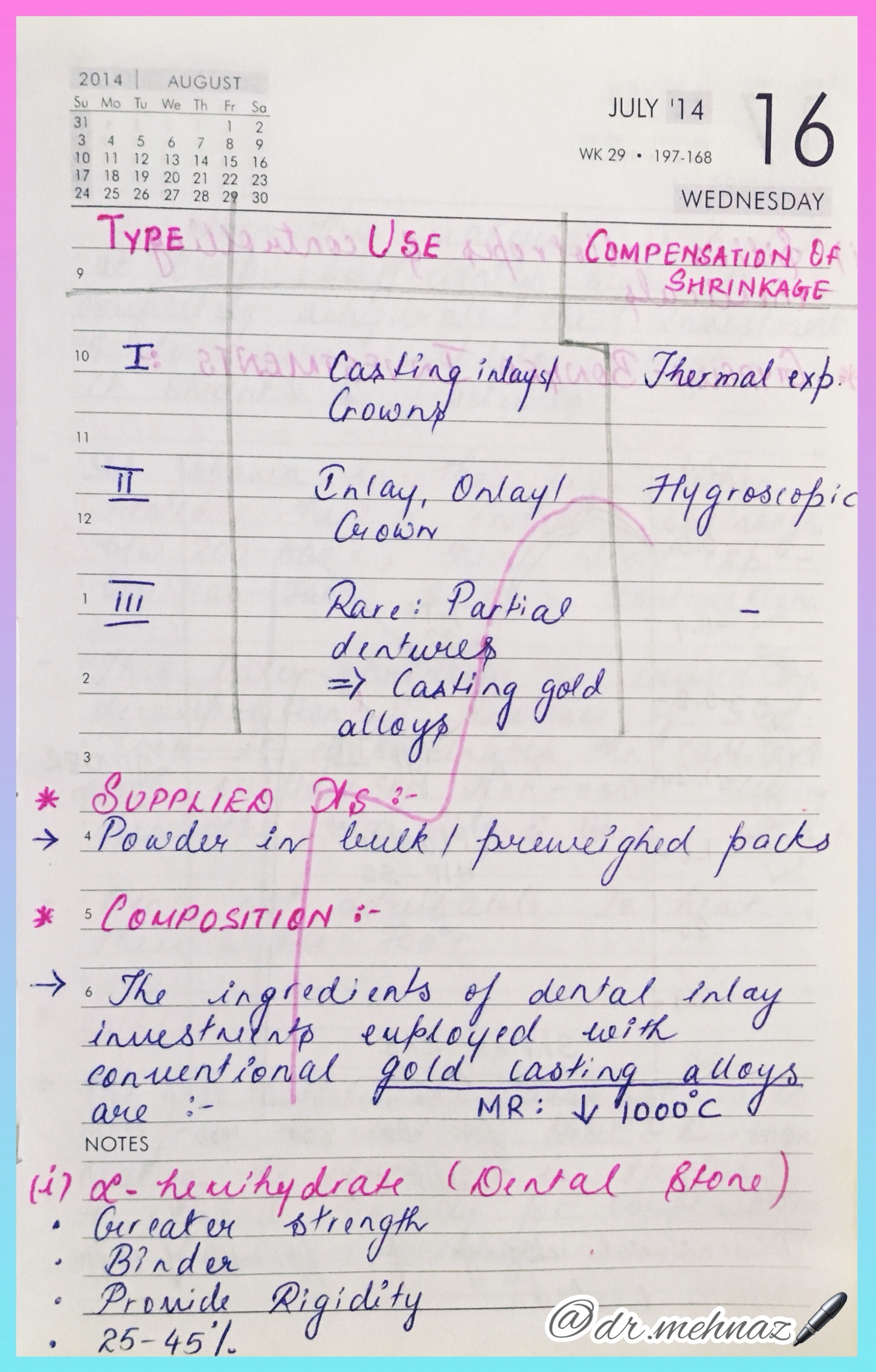

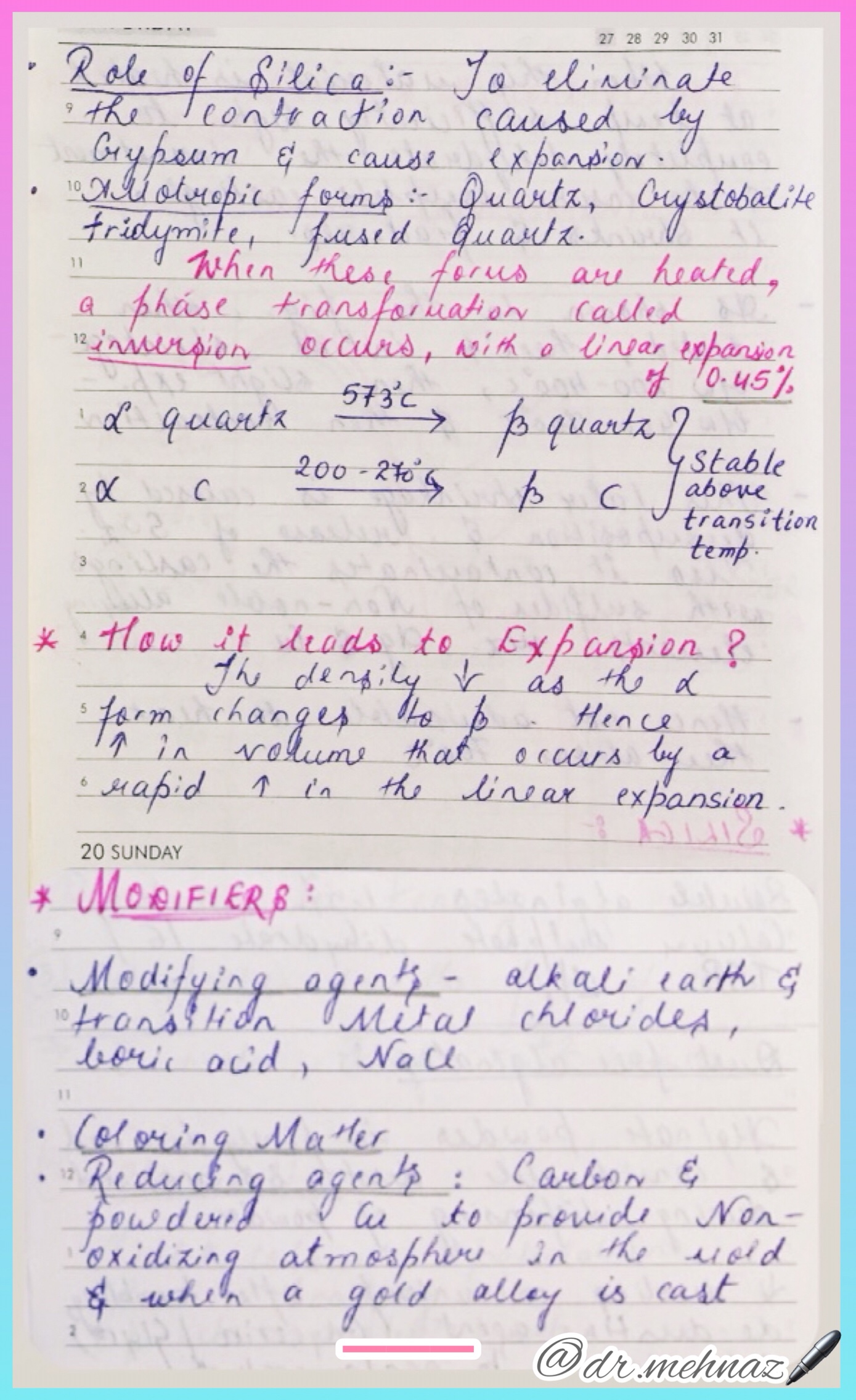

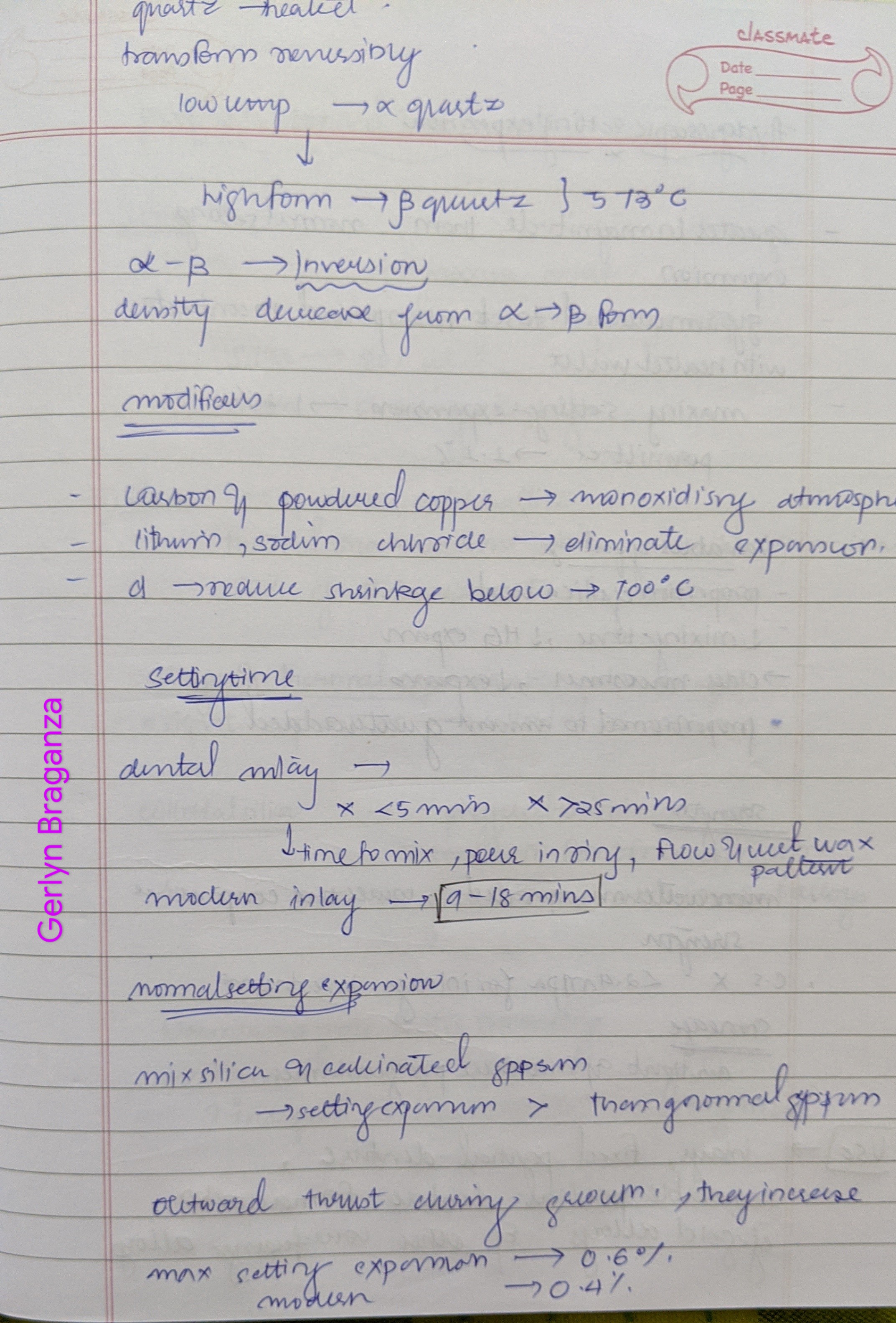

GYPSUM BONDED INVESTMENTS

Thermal behaviour of gypsum

When gypsum is heated to a high temperature, it shrinks and fractures. At 700 °C, it shows slight expansion and then great amount of contraction. The shrinkage is due to decomposition and release of sulphur dioxide .

It contaminates the casting with sulphides of silver and copper .

Hence gypsum bonded investments are not heated above 700°C.

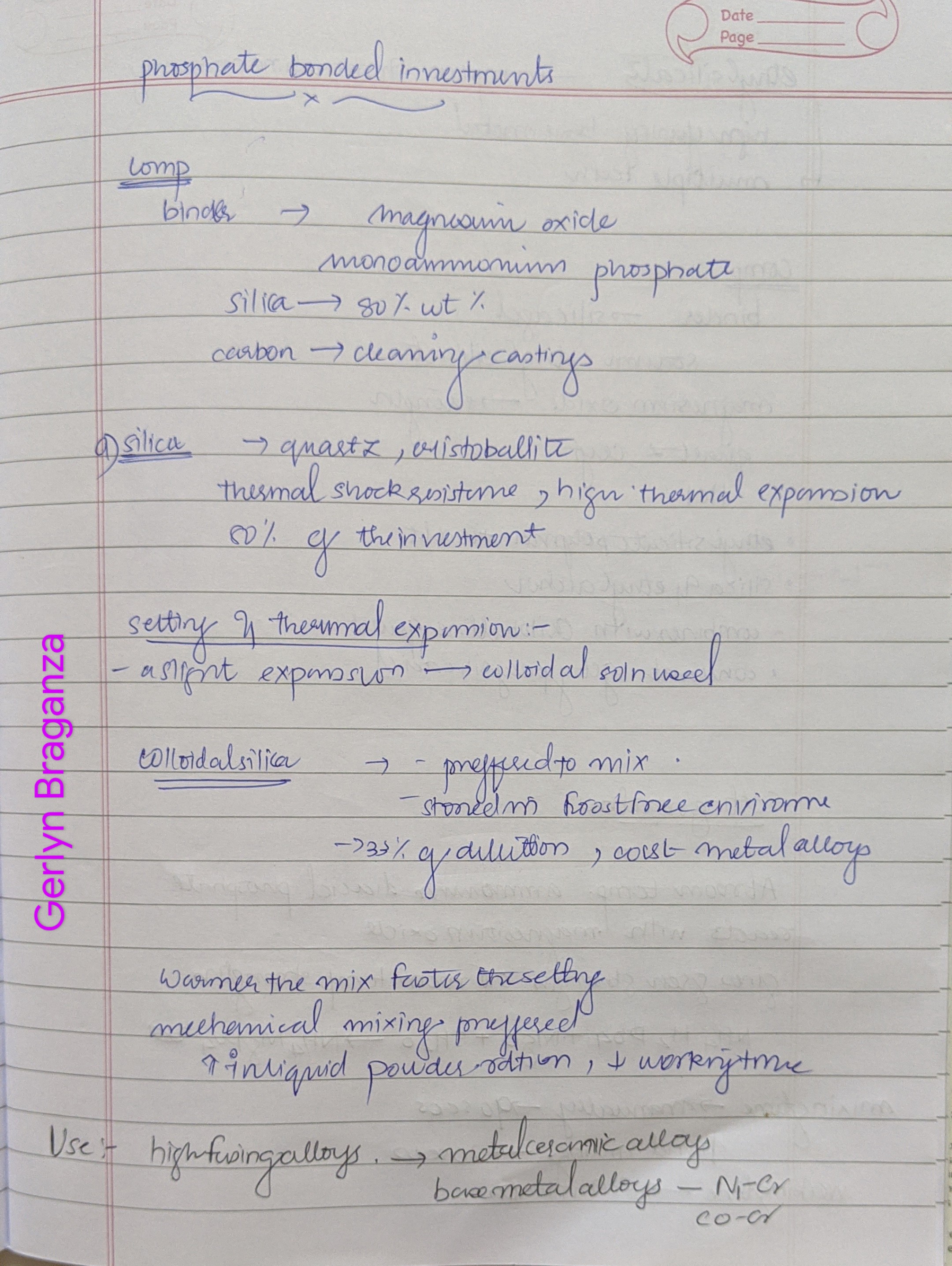

PHOSPHATE BONDED INVESTMENTS

EXPANSION

The amount of expansion is adjusted by the manufacturer for each product depending on the alloy it is intended for.

STRENGTH –

Wet strength ranges from 4-10Mpa

And dry strength is the strength under high temperatures.

SILICA BONDED INVESTMENTS

The silica is the binder. It is derived from ethyl silicate or aqueous dispersion of colloidal silica or sodium silicate.

TYPES

Based on the binder used two types may be seen. One such investment consists of silica refractory, which is bonded by the hydrolysis of ethyl silicate in the presence of hydrochloric acid.

The product of the hydrolysis is the formation of a colloidal solution of silicic acid ethyl alcohol.

Ethyl silicate has the disadvantage of containing inflammable components which are required for manufacture

Sodium silicate and colloidal silica are more commonly used as binders because of the above disadvantage.

These investments are supplied along with two bottles of special liquid. One bottle contains dilute water soluble silicate solution such as sodium silicate.

Source – basic science of dental materials manappallil

A refractory is a non metallic material with can with stand high temperature without degrading , softening or losing its strength.

A investment is a ceramic material which is suitable for forming a mold into which a molten metal or alloy is cast. The process is called investing

REQUIREMENTS OF AN INVESTMENT MATERIAL

GENERAL COMPOSITION of INVESTMENTS

All investment materials contain a refractory, a binder and modifiers.

REFRACTORY

A refractory is a material that will withstand high temperatures without decomposing or disintegrating, e.g. silica.

Allotropic forms Silica exists in at least four allotropic forms.

Quartz

Tridymite

Cristobalite

Fused quartz

They serve two functions

BINDER

A material which will set and bind together the particles of refractory substance,

e.g. gypsum, phosphate and silicate. The common binder used for gold alloys is dental stone (alpha hemihydrate).

The investments for casting cobalt chromium alloys use ethyl silicate, ammonium sulphate or sodium phosphate.

CHEMICAL MODIFIERS

Chemicals such as sodium chloride, boric acid, potassium sulfate, graphite, copper powder or magnesium oxide are added in small quantities to modify properties.

Source – basic science of dental materials – manappallil

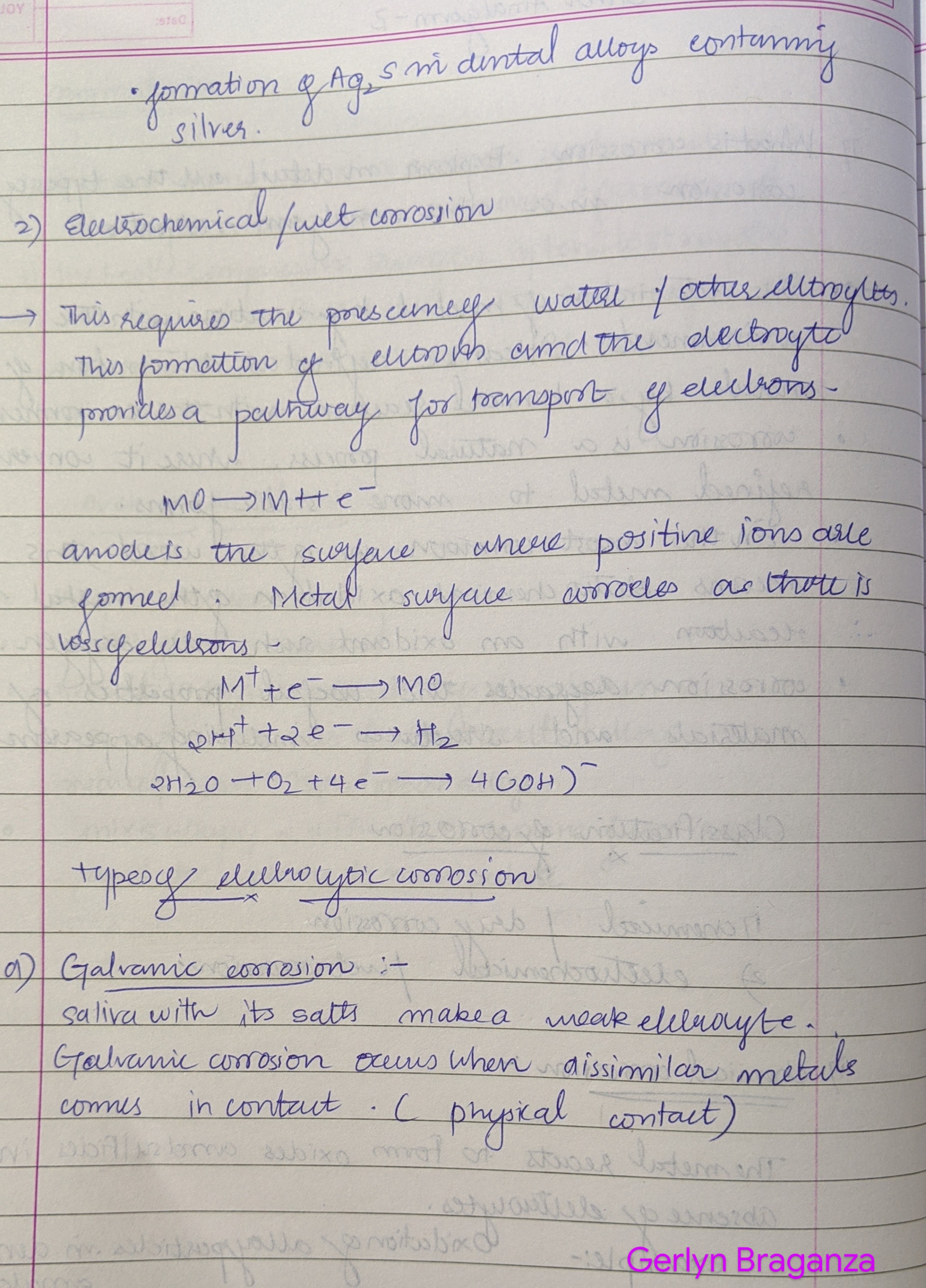

What is corrosion ? And what are its different types ?

Source – basic science of dental materials ( manappallil) and philips

Source – philps science of dental materials and manapalil