As orthodontic students, you’re entering the field at an exciting time of technological innovation. Traditional thermoformed aligners have revolutionized orthodontic treatment, but now we’re witnessing the emergence of direct 3D-printed aligners that promise to transform the way we approach clear aligner therapy.

Understanding Direct 3D-Printed Aligners

Direct 3D-printed aligners are fabricated using specialized photopolymer resins, with Tera Harz TC-85 being the most prominent FDA-approved material. Unlike traditional aligners that are vacuum-formed over printed models, these aligners are printed directly as complete shells, offering unprecedented design flexibility and customization possibilities.

Revolutionary Design Capabilities

What sets direct 3D-printed aligners apart is their unlimited design possibilities. As future orthodontists, you’ll have the ability to:

Fine-tune biomechanics by adjusting the thickness at any part of the aligner, enabling precise force delivery and production of countermoments for root movement. This level of customization was previously impossible with conventional thermoformed aligners.

Incorporate specialized features such as:

- Cutouts and bite ramps for specific clinical situations

- Class II advancement wings similar to functional appliances

- Integrated tubes for TMA spring insertion in cases requiring gap closure after relapse

- Hooks for elastics built directly into the aligner design

- Pressure columns for extrusion movements, eliminating the need for attachments

- Customized trim lines for optimal retention and comfort

Material Properties and Clinical Advantages

Shape Memory Technology

The most remarkable feature of TC-85 resin is its shape memory capability. After exposure to high temperatures, aligners can be deformed to easily snap over undercuts, but when maintained in the oral environment (above 30°C) for the prescribed 22 hours daily, any deformation self-corrects. This property ensures consistent force delivery throughout the treatment period.

Force Delivery Characteristics

Research demonstrates that direct 3D-printed aligners apply continuous, light forces due to their unique viscoelastic properties. Studies show that force levels during extrusion movements are significantly lower compared to thermoformed aligners, potentially reducing patient discomfort and unwanted side effects.

The ability to customize thickness at different aligner regions allows for better force distribution, optimizing tooth movement while minimizing adverse effects. This represents a significant advancement in biomechanical control that you’ll appreciate in your clinical practice.

Durability and Performance

TC-85 aligners maintain their mechanical properties for at least one week of intraoral use. Unlike thermoplastic aligners, they can remain at body temperature without losing force from deformation, ensuring consistent treatment progression. However, surface roughness and porosity increase after one week of wear, similar to conventional aligners.

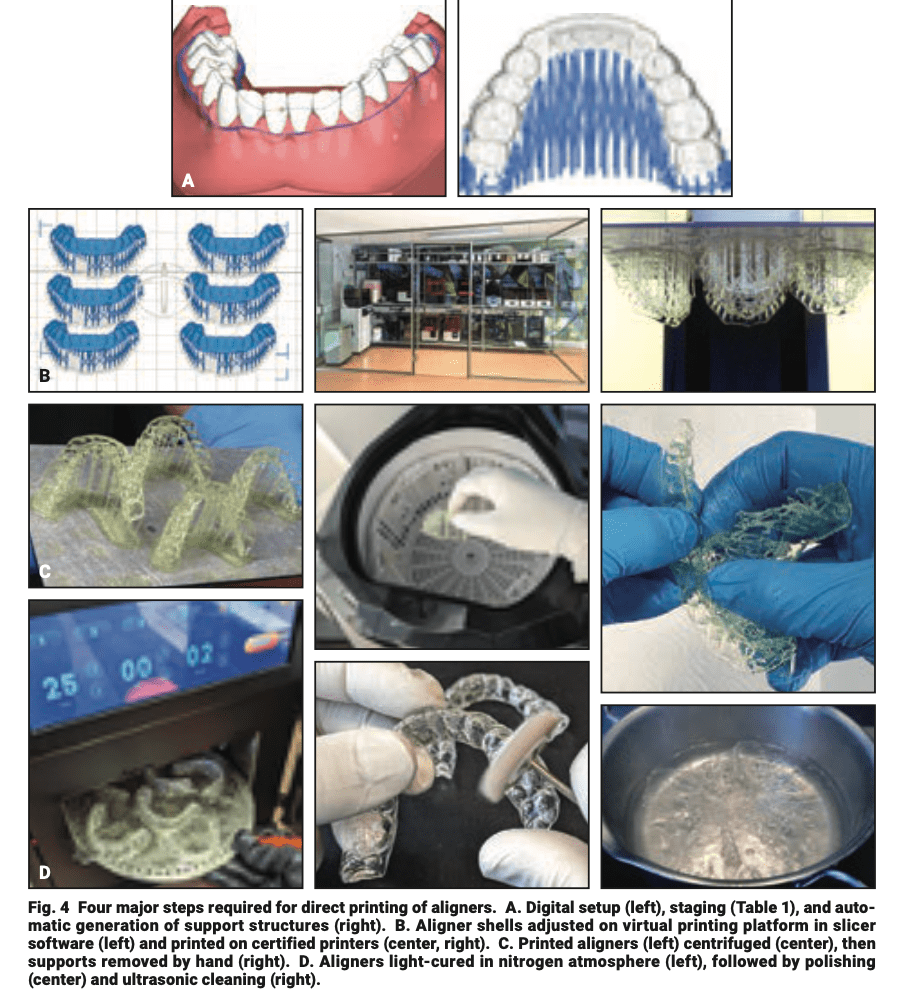

Workflow Steps

- Digital Setup & Staging

– Software platforms (e.g., Graphy DAD)

– Movement limits: 0.25–0.30 mm per tooth; ≤2° angulation - 3D Printing

– 6–8 aligners per run (30–60 min) - Cleaning & Support Removal

– Centrifuge 6 min; manual support removal - Post-Processing

– UV cure (17–25 min in N₂); polish; ultrasonic clean

Software Tools

- Graphy Direct Aligner Designer (free)

- Commercial: 3Shape, Blue Sky Plan, NemoStudio

📌 Source: Ludwig B, Ojima K, Schmid JQ, Knode V, Nanda R. Direct-Printed Aligners: A Clinical Status Report. J Clin Orthod. 2024;58(11):658–668